Precautions

Our complete set of post-processing equipment includes waste oil collector, air-cooled cold dryer, high-efficiency oil remover, high-efficiency air cooler, blast regeneration adsorption dryer, zero-loss waste heat regeneration adsorption dryer, water-cooled cold dryer, micro-heat regeneration adsorption dryer, heatless regeneration adsorption dryer, compressed air precision filter, compressed air oil-water separator, compressed air pre-cooling unit, compression heat regeneration adsorption dryer, vacuum filter, self-cleaning air compressor suction filter, combined dryer.

Post-processing equipment can be matched to your desired effect according to your different needs and uses.

Product Introduction

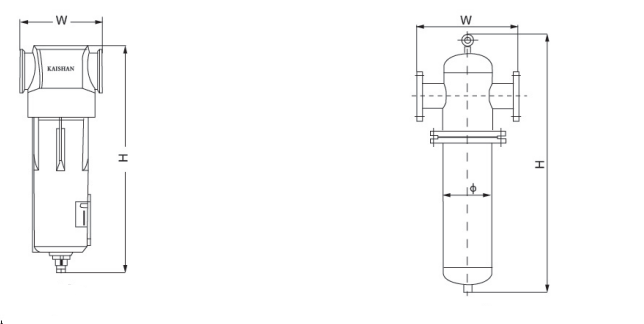

Unpurified compressed air contains pollutants such as oil mist, solids, impurities, and water. These pollutants are the natural enemies of modern industry to improve product quality and labor efficiency. KSAF series compressed air precision filter is the core product of Kaishan Purification Equipment Co., Ltd. It can effectively remove liquid water, dust and oil from compressed air. This series of filters are divided into two types: threaded connection (aluminum alloy shell) and flange connection (steel shell).

Product Features

Overall design

■The high-end filter is equipped with a sight glass to detect whether the drain is blocked.

■The die-casting mold is carefully designed to ensure uniform product thickness and safe use.

■The raw material uses grade A aluminum ingots to ensure product quality.

Good anti-corrosion performance

■The inner cavity of the filter housing is anodized and the outer surface is sprayed with epoxy resin dry powder.

Good filter material performance

■The filter element adopts the British PSI special anti-leakage online detection technology to ensure the filtration accuracy.

■The American LYDALL brand borosilicate nano-glass fiber has high dust holding capacity and long life, and the special oleophobic and hydrophobic chemical treatment ensures that the high pressure is reduced during filtration.

■The folded filter element is used to greatly increase the filtration area and reduce the pressure drop by 50%, and improve the particle carrying capacity. The stainless steel inner and outer support nets enhance the stability of the filter element.

Humanized design

■The gas flow direction indicator makes it easy for operators to install and maintain the product.

■The flange filter housing adopts a humanized design, which makes it easy to replace the filter element.

■The tightening mark allows operators to clearly know whether the product is tightened in place to prevent improper force and air leakage.

Technical drawings

Let’s talk about it

- WhatsAppWhatsApp:86-13361850253

- Call UsCall Us:86-18576725825