Technical advantages

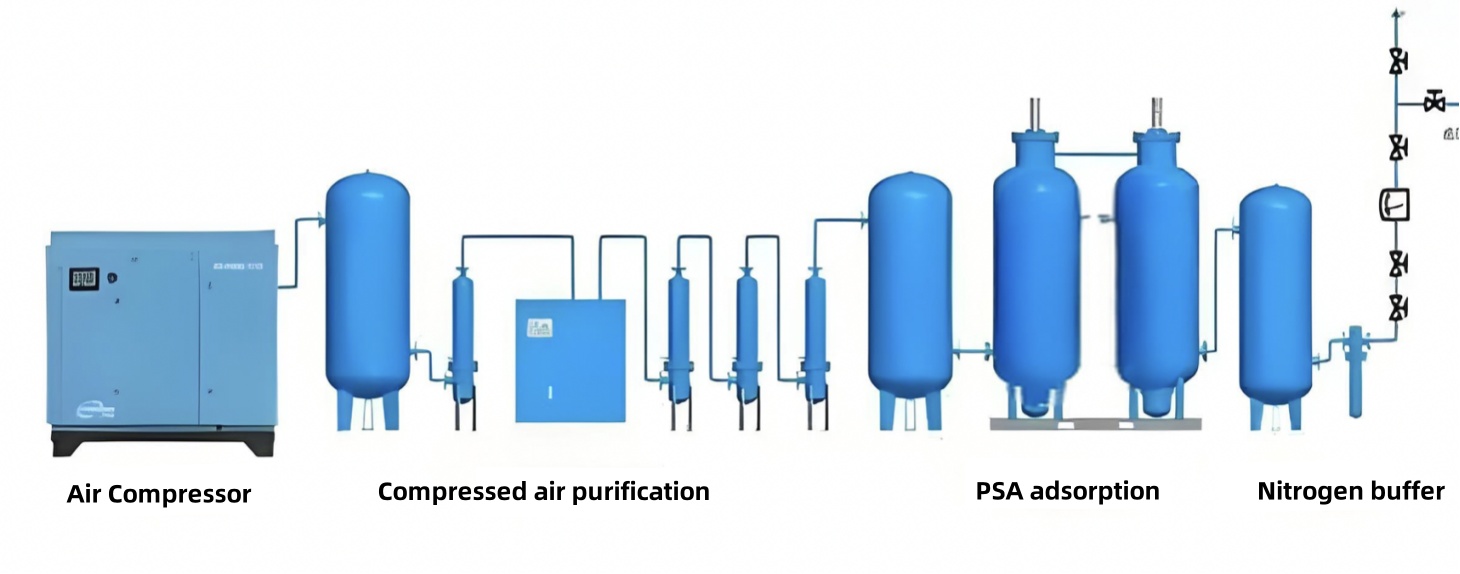

1.Advanced process:

With reference to the international advanced technical solutions, the process design of two adsorption towers is adopted, and the advanced short process is applied to improve the utilization rate and adsorption efficiency of carbon molecular sieves, ensure the service life of molecular sieves, improve the adsorption performance, and reduce the demand for compressed air.

2.Filling process

The filling technology adopts a vibration filling method that combines internal and external filling methods. The filling density of the carbon molecular sieve is greatly improved, and the collision between the molecular sieves is controlled to prevent the carbon molecular sieve from loosening and pulverizing.

3.Advantages

The nitrogen generator has been optimized and designed to overcome the defects of the PSA nitrogen generator system and improve the reliability and service life of the equipment. The time from startup to the output of qualified nitrogen is within 15 minutes.

4.Adaptive function

Product purity and flow rate can be continuously adjusted to meet the production needs of customers; it can automatically adapt to the actual use status of users. When the nitrogen outlet parameters are adjusted, the nitrogen production equipment control system can select different process solutions to ensure the customer's demand for nitrogen and achieve the effect of energy saving and consumption reduction.

5.Simple structure

The equipment adopts an integrated skid-mounted structure, which is simple and reasonable, easy to install and maintain. The control system adopts PLC + HMI, and the nitrogen production system is fully automatically controlled, which can automatically diagnose faults and issue alarms. It can realize unmanned operation and has remote monitoring function.

Main application areas

Metallurgy and metal processing industry

The pressure swing adsorption nitrogen generator for metallurgy and metal processing industry can obtain nitrogen with a purity greater than 99.5%. Through the joint use with nitrogen purification equipment, the purity is greater than 99.999% and the dew point is lower than -65C. High-quality nitrogen. It is used for annealing protective gas, sintering protective atmosphere, nitriding treatment, furnace washing and purging gas, etc. It is widely used in metal heat treatment, powder metallurgy, magnetic materials, copper processing, metal wire mesh, galvanized wire, semiconductor, powder reduction and other fields. It is suitable for heat treatment, bright annealing, protective heating, powder metallurgy, copper and aluminum processing, magnetic material sintering, precious metal processing, bearing production and other fields. It has the characteristics of high purity, continuous production, and some processes require nitrogen to contain a certain amount of hydrogen to increase brightness.

Chemical and new materials industries

Nitrogen with a purity greater than 98% or the required purity is obtained through a pressure swing adsorption nitrogen generator. It is mainly used for chemical raw material gas, pipeline purging, atmosphere replacement, protective atmosphere, product transportation, and is mainly used for covering, replacement, cleaning, pressure transportation, chemical reaction stirring, chemical fiber production protection, nitrogen filling protection and other fields. It is suitable for petrochemical, coal chemical, salt chemical, natural gas chemical, fine chemical, new materials and their derivative chemical product processing, ammonia rubber, plastics, tires, polyurethane, biotechnology, intermediates and other industries. It is suitable for nitrogen protection and molding in the vulcanization process of rubber and tire production. Especially in the production of all-steel radial tires, the new nitrogen vulcanization process has gradually replaced the steam vulcanization process. It has the characteristics of high nitrogen purity, continuous production, and high nitrogen pressure.

Coal mining industry

Nitrogen with a purity greater than 95% or the required purity is obtained through a pressure swing adsorption nitrogen generator. It is suitable for fire prevention and extinguishing, gas and coal gas dilution in coal mining, and has three specifications: ground fixed, ground mobile, and underground mobile, which fully meet the nitrogen demand under different working conditions. Explosion-proof nitrogen generators are suitable for chemical, petroleum and natural gas and other places with explosion-proof requirements for equipment.

Oil and Gas Industry

Nitrogen with a purity greater than 98% or the required purity is obtained through a pressure swing adsorption nitrogen generator. The special nitrogen generator for the petroleum and natural gas industry is suitable for nitrogen protection, transportation, covering, replacement, emergency rescue, maintenance, nitrogen injection and oil production in mainland oil and natural gas production, coastal and deep-sea oil and natural gas production. It has the characteristics of high safety, strong adaptability and continuous production.

Food and pharmaceutical industries

Nitrogen with a purity greater than 97% or 99.9% is obtained through a pressure swing adsorption nitrogen generator. Through sterilization, dust removal, water removal and other treatments, high-quality nitrogen is obtained to meet the special requirements of the industry. It is mainly used in the fields of pharmaceutical production, storage, packaging, and packaging. It is mainly used in food nitrogen packaging, green grain storage, food preservation, pharmaceutical packaging, pharmaceutical replacement gas, pharmaceutical delivery atmosphere, vegetable preservation, wine sealing (canning) and preservation, etc.

Electronics Industry

Nitrogen with purity greater than 99.9% or 99.999% is obtained through a pressure swing adsorption nitrogen generator, or high-quality nitrogen with purity greater than 99.9995% and dew point lower than -65°C is obtained through nitrogen purification equipment. Nitrogen generator has the characteristics of high purity, small size, low noise and low energy consumption. It is used in the fields of electronic product packaging, electronic component production, LED, LCD liquid crystal display, lithium battery production, sintering, annealing, reduction, storage, etc. It is mainly used in wave soldering, reflow soldering, crystal, piezoelectric electronic ceramics, electronic copper strip, battery, electronic alloy material and other industries.

Automotive, Transportation and Mobility

Containerized nitrogen generators are suitable for oil, natural gas, chemical industry and other related fields, with strong adaptability and mobile operation. Vehicle-mounted mobile nitrogen generators are suitable for the mining, pipeline purging, replacement, emergency rescue, dilution of flammable gas and liquid in the oil and gas industry. They are divided into low-pressure, medium-pressure and high-pressure series, with strong mobility and mobile operation. Nitrogen generators for automobile tires are mainly used for nitrogen flushing of automobile tires in automobile 4S stores and automobile repair shops, which can extend the service life of tires and reduce noise and fuel consumption.

Other areas of use

In addition to the above industries, nitrogen generators are also widely used in many fields such as coal, petroleum, and oil transportation. With the advancement of science and technology and the development of society, the use of nitrogen is becoming more and more extensive. On-site gas generation (nitrogen generator) has gradually replaced traditional nitrogen supply methods such as liquid nitrogen evaporation and bottled nitrogen with its advantages of low investment, low cost, and convenient use.

Recommend Products

Get A Free Quote

ASK YOUR QUESTIONS

Ready to start a project?

Let’s talk about it

Let’s talk about it

Your satisfaction is our biggest pursuit, if you have any questions and want to know, please fill in the next form to send your feedback or suggestions to us, we will reply you as soon as possible.

- WhatsAppWhatsApp:86-13361850253

- Call UsCall Us:86-18576725825