Heatless regeneration adsorption dryer

Post-processing equipment cannot be split and purchased separately. You must first purchase our air compressor before you can purchase our modified post-processing equipment.

Unit:SET

Price:Market price

Price Clause:FOB

Precautions

Our complete set of post-processing equipment includes waste oil collector, air-cooled cold dryer, high-efficiency oil remover, high-efficiency air cooler, blast regeneration adsorption dryer, zero-loss waste heat regeneration adsorption dryer, water-cooled cold dryer, micro-heat regeneration adsorption dryer, heatless regeneration adsorption dryer, compressed air precision filter, compressed air oil-water separator, compressed air pre-cooling unit, compression heat regeneration adsorption dryer, vacuum filter, self-cleaning air compressor suction filter, combined dryer.

Post-processing equipment can be matched to your desired effect according to your different needs and uses.

Product Introduction

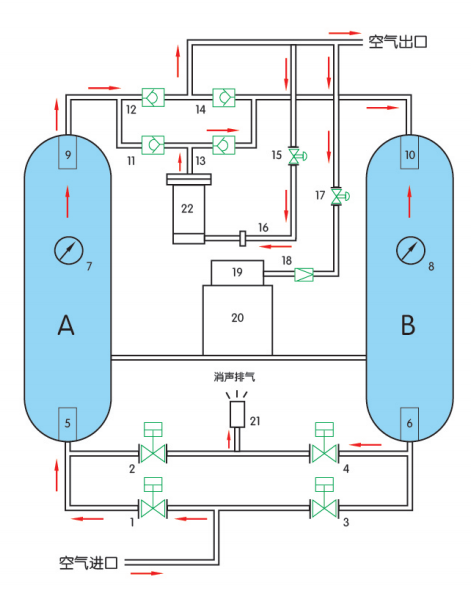

This series of products combines the advantages of thermal regeneration and non-thermal regeneration. It uses micro-heating for the regeneration gas, thereby reducing the regeneration gas consumption and achieving energy saving. It avoids the shortcomings of short switching time and large regeneration air loss of the non-thermal regeneration dryer, and also avoids the shortcomings of large power loss of the thermal regeneration air dryer. The dryer has a reasonable switching time and low regeneration gas consumption. It is the most economical energy-saving adsorption dryer in the chemical industry and is widely used in metallurgy, electricity, electronics, food, chemical industry, petroleum, medicine, textile, tobacco, instrumentation, automatic control and other industries.

Working conditions and technical indicators

Design pressure dew point: standard -20℃ (-40℃, -70C products are available)

Inlet temperature: 20~45℃

Working pressure: 0.6~1.0Mpa

Desiccant: standard activated alumina, low dew point product activated alumina and 5A molecular sieve group

Working mode: two adsorption cylinders work alternately and continuously

Control mode: microcomputer program control

Inlet oil content: ≤0.1PPM

Pressure loss: ≤3% of inlet pressure

Regeneration gas volume: ≤6~8%

Regeneration method: micro-heat regeneration

Heater voltage: 1~8Nm/min, 220V10Nm3/min and above is 380V

Cycle: 1~20Nm/min, 120 minutes; 25~50Nm/min, 240 minutes;

60~100Nm²/min, 360 minutes; 100Nm/min, 480 minutes;

Installation method: foundation-free installation

Technical drawings

Recommend Products

Get A Free Quote

ASK YOUR QUESTIONS

Ready to start a project?

Let’s talk about it

Let’s talk about it

Your satisfaction is our biggest pursuit, if you have any questions and want to know, please fill in the next form to send your feedback or suggestions to us, we will reply you as soon as possible.

- WhatsAppWhatsApp:86-13361850253

- Call UsCall Us:86-18576725825