Oil removal and sterilization air purifier

Unit:SET

Price:Market price

Price Clause:FOB

Provide you with 100% oil-free, sterile and high-quality compressed air

Compressed air cleanliness grade standard

Compressed air quality in accordance with ISO 8573-1

The oil content is defined in grades according to ISO 8573.

In addition to the oil content, the moisture and particle content are also specified in the compressed air grades.

| ISO8573-1,2010 | Oil content: liquid, aerosol, oil vapor |

|---|---|

| Grade | mg/m³ |

| 0 | More stringent requirements than Level 1 |

| 1 | ≤0.01 |

| 2 | ≤0.1 |

| 3 | ≤1 |

| 4 | ≤5 |

Oil-free air compressor ≠ Oil-free compressed air

Since oil-free compressors cannot guarantee that the air sucked in is absolutely oil-free during the air compression process, and daily life, industrial production, automobile exhaust, etc. will produce oil pollutants, the oil content in the atmosphere cannot be guaranteed to be lower than the oil-free standard of 0.01mg/m³ (eqv. ISO8573.1) Class 1 residual oil standard. Therefore, the compressed air produced by oil-free compressors often contains oil impurities.

Can stably provide Class 0 oil-free and sterile compressed air

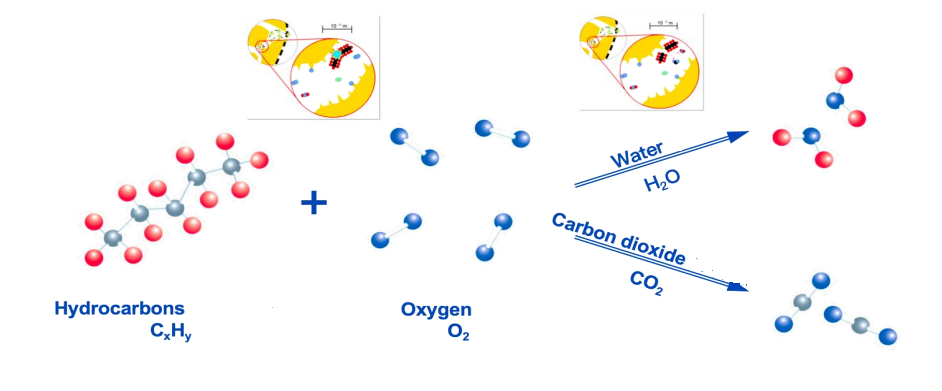

When the oil removal purifier purifies compressed air, the specially developed granular material is heated to 150℃-220℃ in the pressure reaction vessel. The oil and hydrocarbons (1) in the compressed air passing through the heated reaction vessel are completely converted into water and carbon dioxide (3) on the microporous inner surface of the purifier granular material (2). The hydrocarbons, oil and organic compounds in the compressed air are removed and the compressed air flows out of the reaction vessel. At the same time, the condensate produced during the cooling process of the compressed air has no residual oil and can be directly discharged into the sewer without further treatment.

Product features of oil removal sterilization purifier

1.Process system optimization and upgrade

The overall system is more optimized and the performance is better

2.Modular design

Modular design, good equipment scalability and multi-component flow diversion processing ensures uniformity of airflow in a single reactor, improves catalyst processing efficiency, and ensures more stable equipment operation

3.A new generation of catalysts

Using TOW catalyst for oil removal is more efficient and reliable

4.Frequency conversion operation

It can achieve a minimum of 10% of the equipment's rated capacity.

5.Self cooling system

After high-temperature catalysis, the compressed air enters the purifier cooler, which can effectively reduce the compressed air temperature below 40°C, greatly reducing the workload of the post-processing equipment.

6.Non-stop maintenance

The equipment can be maintained during online operation without affecting production and use

7.Internet of Things module (optional)

It can realize online cloud management and control, saving time, effort and worry

8.Activated carbon bypass (optional)

The equipment can automatically switch to activated carbon filter (component), eliminating the waiting time during the equipment preheating phase, while ensuring continuous operation in the event of equipment failure

PRODUCT ADVANTAGE:Large energy saving. Used with ordinary air compressor, it can save 30%-50% energy compared with oil-free compressor.

Continuously and stably provide Class 0 oil-free and bacteria-free compressed air in accordance with GB/T13277.1-2008 (eqv.ISO8573.1) standard

Continuously and stably provide Class 0 oil-free and bacteria-free compressed air in accordance with GB/T13277.1-2008 (eqv.ISO8573.1) standard

Not affected by ambient temperature, oil or water content of inlet compressed air

Not affected by ambient temperature, oil or water content of inlet compressed air

Real-time monitoring of multiple points in the system and an independent emergency protection system ensure that the downstream air system is not polluted

Real-time monitoring of multiple points in the system and an independent emergency protection system ensure that the downstream air system is not polluted

Compared with oil-free compressors, the total purchase cost of matching ordinary air compressors is lower

Compared with oil-free compressors, the total purchase cost of matching ordinary air compressors is lower

One-button operation, simple maintenance, touch-screen human-machine interaction interface

One-button operation, simple maintenance, touch-screen human-machine interaction interface

No noise, no toxic or harmful pollutants, the condensate of the treated gas can be discharged directly

No noise, no toxic or harmful pollutants, the condensate of the treated gas can be discharged directly

Easy to install, can be directly installed into the existing compressed air system

Easy to install, can be directly installed into the existing compressed air system

Safety certification of your processes with oil-free and sterile compressed air

Together with TÜV Nord, it has been demonstrated that under real operating conditions, the compressed air treated by the Ledewoer degreasing sterilization and purification system outperforms the Class 1 standard of ISO8573-1. In a series of tests conducted by the Organization for the Certification of Hygienic and Sterile Production (GfPS), it was confirmed that the Ledewoer degreasing sterilization and purification system has sterilized compressed air contaminated with bacteria. After treatment, no live bacteria were detected in the compressed air flow.

Equipment selection technical parameters

| Item | LE80 | LE150 | LE260 | LE400 | LE600 | LE800 | LE1000 | LE1200 | LE1600 |

|---|---|---|---|---|---|---|---|---|---|

| Handling traffic(m³/min) | 0.8 | 1.5 | 2.5 | 4 | 6 | 8 | 10 | 12 | 16 |

| Maximum working pressure(bar) | 11 | 11 | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| Power supply | 220V/50HZ | 220V/50HZ | 220V/50HZ | 220V/50HZ | 220V/50HZ | 220V/50HZ | 220V/50HZ | 220V/50HZ | 220V/50HZ |

| Operating power | 0.5 | 1.5 | 2.0 | 2.2 | 3.0 | 3.4 | 4.0 | 4.5 | 5.5 |

| Interface size | G1/2 | G3/4 | G1 | G1 1/4 | G1 1/2 | G2 | G2 | DN65 | DN65 |

| Length(MM) | 465 | 465 | 680 | 680 | 1100 | 1185 | 1185 | 1200 | 1350 |

| Width(MM) | 330 | 330 | 550 | 500 | 500 | 480 | 480 | 560 | 620 |

| Height(MM) | 850 | 850 | 1070 | 1070 | 1550 | 1480 | 1480 | 1580 | 1600 |

| Unit weight(KG) | 150 | 165 | 200 | 255 | 315 | 380 | 450 | 520 | 600 |

| Item | LE2000 | LE2400 | LE3000 | LE4000 | LE500 | LE6000 | LE7000 | LE8000 | LE10000 |

|---|---|---|---|---|---|---|---|---|---|

| Handling traffic(m³/min) | 20 | 24 | 30 | 40 | 50 | 60 | 70 | 80 | 100 |

| Maximum working pressure(bar) | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| Power supply | 220V/50HZ | 220V/50HZ | 220V/50HZ | 220V/50HZ | 220V/50HZ | 220V/50HZ | 220V/50HZ | 220V/50HZ | 220V/50HZ |

| Operating power | 6.0 | 7.5 | 9.6 | 12.5 | 14.2 | 15.5 | 17.0 | 18.5 | 21.2 |

| Interface size | DN80 | DN80 | DN100 | DN100 | DN125 | DN125 | DN150 | DN150 | DN200 |

| Length(MM) | 1400 | 1400 | 1500 | 1580 | 1600 | 1685 | 1720 | 1800 | 1950 |

| Width(MM) | 650 | 680 | 720 | 750 | 800 | 880 | 920 | 960 | 1020 |

| Height(MM) | 1660 | 1650 | 1720 | 1770 | 1820 | 1880 | 1900 | 1940 | 2000 |

| Unit weight(KG) | 750 | 820 | 950 | 1155 | 1300 | 1420 | 1560 | 1650 | 180 |

Recommend Products

Get A Free Quote

ASK YOUR QUESTIONS

Ready to start a project?

Let’s talk about it

Let’s talk about it

Your satisfaction is our biggest pursuit, if you have any questions and want to know, please fill in the next form to send your feedback or suggestions to us, we will reply you as soon as possible.

- WhatsAppWhatsApp:86-13361850253

- Call UsCall Us:86-18576725825